Initial Production Check (IPC) is performed at the stage of about 5%-10% products finished for inspection, to allow the review of product quality requirements before mass production begins. Permit timely corrections of any non-conformities detected, and improvements action to be made prior to the commencement of mass production

During Production Inspection (DPI) is performed at the stage of 30%- 50% goods finished and packed into export cartons. This inspection validates the initial production process has been maintained and that goods being produced continue to meet quality requirements. In the case of new raw materials, new operators, production lines or specification changes, this service can assess if requirements are being met during production.

Final Random Inspection (FRI) is a most effective inspection that confirms the whole shipment's quality level. It normally requires the production to be 100% complete and at least 80% of goods to be packed into cartons. The checked samples are randomly selected according to AQL standard.

When the product is 100% finished, before or after the products are packaged, we check the appearance, workmanship, function, safety of each product according to the customer's requirements at the location specified by the customer. We can strictly distinguish product quality and report the results of inspections to customers timely.

sampling picking service ensures that the samples are collected randomly from mass production batch in order to counter "pre-arranged" samples arranged by factories to represent mass production batches.

Loading Supervision provides witness to the loading process, to make sure the correct quantity and good condition cartons are loaded into good condition containers.

It is a service to audit supplier of files & on site review, get the real information, then evaluate supplier' s legal qualification, organizer chart, worker groups, facilities, production capacity and internal quality management. To ensure the business proceed correctly in safety, quality, action, production and shipment before order issued. Normally, we will do the assessment service according to the checklist.

Initial Production Check (IPC)

During Production Inspection (DPI)

Final Random Inspection (FRI)

100% Inspection

Sampling Picking Service

Loading Supervision

Factory Assessment

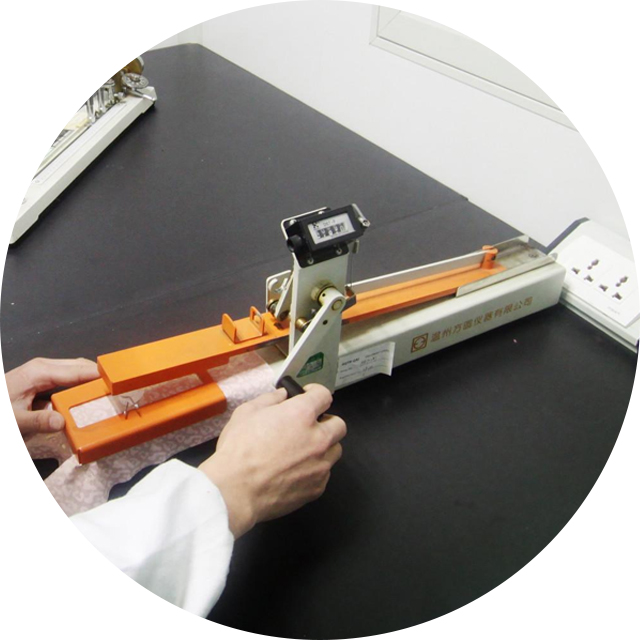

Soft Goods

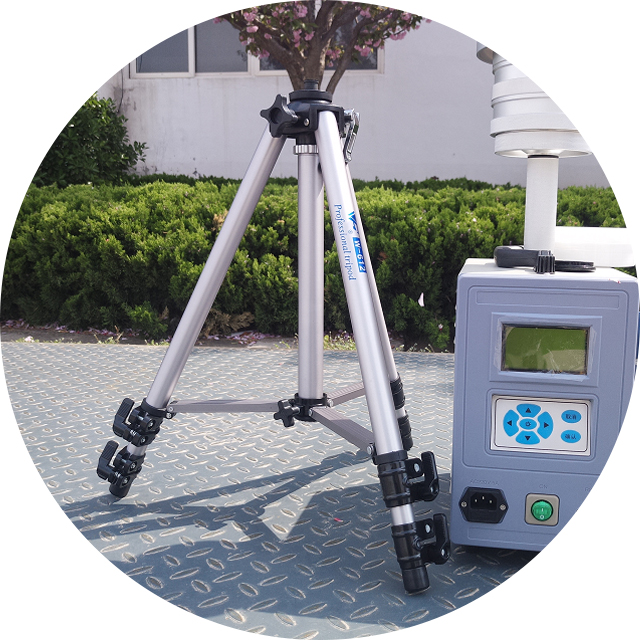

Electrical & Electronic Items

Hard Goods

Compliance & Integrity

Company Culture

Our Advantages

Sample Report

Copyright © Ceneni - 2020